Get to know us

Our History

Since 2024, SUIMED, from its workshop located in the ATALAYAS industrial area in Alicante, Spain, has embarked on a new phase focused on the manufacturing and integration of industrial equipment to offer its clients customized, intelligent, and cost-effective solutions tailored to their technical and economic requirements.

Our

Mission

We offer customized industrial engineering solutions, providing high-quality materials and ensuring optimized industrial and logistics processes.The company aims to be a leader in the food industry in general, and specifically in the dairy and beverage sectors — not only as a supplier of equipment, but also by supporting clients throughout the design of their projects, commissioning, and training of their teams.We guarantee efficient and prompt maintenance service, as well as ongoing support as part of your team.

Our

Products

Pasteurizadores

Custom-made and personalized milk pasteurizers

01

Complete stations

Complete milk receiving stations according to needs

02

Tanks

Tanks of all types and various capacities

03

Complete systems

Complete CIP systems with various capacities

04

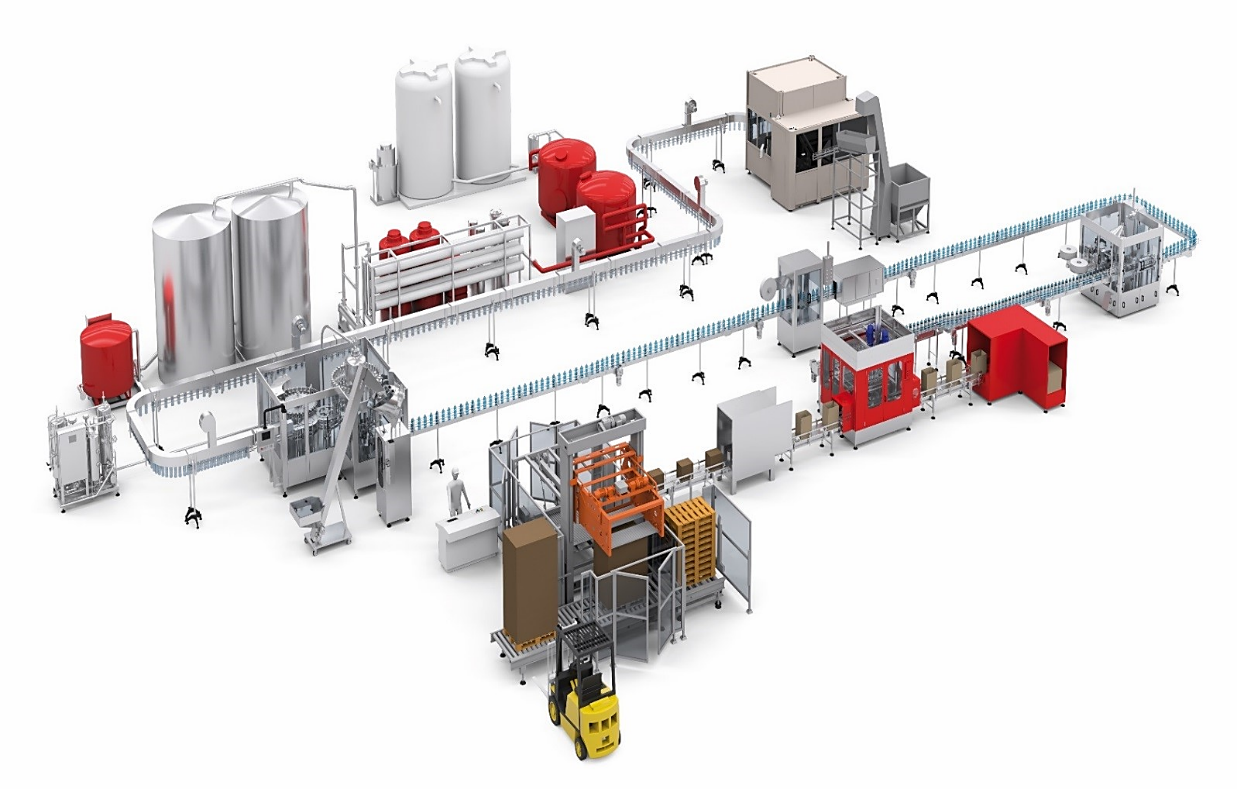

Lines

Bottling lines

05

Reception of milk

- Fast and efficient milk cooling

- Minimizing the reproduction of microorganisms

- Combining the most modern technologies for milk preservation, disinfection, and long-term reliability in a compact and easy-to-use milk cooling tank

Pasteurizers

- HTST pasteurization (High Temperature Short Time) is a process that extends the shelf life of a quality product without significantly altering its organoleptic properties. It involves heating the product to a temperature ranging from 72°C to 95°C and maintaining the pasteurization temperature for a predetermined period.

- ESL milk (Extended Shelf Life) is a product subjected to higher pasteurization temperatures than those traditionally used, resulting in a longer shelf life while remaining within the cold chain.

Small dairy

- Mini dairy line designed for the processing and production of small quantities of raw materials. The developed equipment allows the production of cheese, yogurt, milk, and curd through a proper combination of the components.

- The design and materials comply with hygiene standards for food production.